Hattons Originals OO Class 66 (2019)

Model overview

66206 at Barton in June 2016. ©Clagmaster

66206 at Barton in June 2016. ©Clagmaster

Class 66

Scale: OO Gauge (1:76 Scale)

Manufacturer: Hattons Originals - Manufacturer Profile

First Introduced: 2019

DCC Capability: DCC Ready. 21-pin socket

Manufacturer: Hattons Originals - Manufacturer Profile

First Introduced: 2019

DCC Capability: DCC Ready. 21-pin socket

Articles, Videos and Other Links

Bodyshell

Bodyshell

Bodyshells represented (of Prototypes) |

Class 66 - Low emissions Class 66 - Standard, as introduced |

Detailing

Detailing

Bodyshell - factory-fitted separate details |

Bodyside doors Door handles Door steps Etched horn grille Exhausts Handrails High intensity headlight Horn(s) Lamp irons Nameplates - etched - pre-fitted Pipe work Release valve Representation of internal equipment (behind grilles) Roof grilles (etched) Side grilles (etched) Wing mirrors |

Bufferbeam detail (in detailing pack) |

NEM Couplings Pipework (for front) Pipework (for rear) Valances |

Bufferbeam detail (pre-fitted) |

Cosmetic screw link coupling Front valance Multiple working sockets/ pipes Pipework - pre-fitted to front Pipework - pre-fitted to rear Sprung buffers |

Cab, footplate & interior detail |

Detailed & painted Glazing Seating Window wipers |

Chassis/underframe detail |

Battery box Footsteps Fuel tank Pipework Sand boxes Sanding gear Speedometer cable |

Wheel "aesthetics" |

Chemically-blackened Compensated axles Metal-pin point bearings Painted |

Mechanical

Mechanical

Body Construction |

Plastic with metal parts |

Chassis construction |

Heavy diecast |

Coupling socket/mounting |

NEM pockets |

Coupling type |

Tension lock |

Loco-driven wheels (number of) |

12 wheels |

Minimum radius |

Radius 2 |

Separating the body from the chassis |

Use plastic card (credit card format ideal) to slide between lower body and chassis, then undo lugs |

Weighting (to assist adhesion) |

Within body Within chassis |

Working cosmetic features |

Rotating Axleboxes |

Electrical

Electrical

DCC Capability: |

DCC Ready. 21-pin socket |

DCC speaker |

Provision for 65mm x 29mm x 14mm speaker (Hattons Rail Rumble) |

Motor location |

Centre of chassis |

Motor type |

5-pole with two flywheels |

Pickups |

All wheels |

Power collection |

2 rail DC |

Working lights |

Cab light Day/ Night modes Directional headlights & tail lights |

Liveries manufactured

Products from this Tooling

Show:

Other versions of this tool

Other OO Gauge (1:76 Scale) Class 66 models

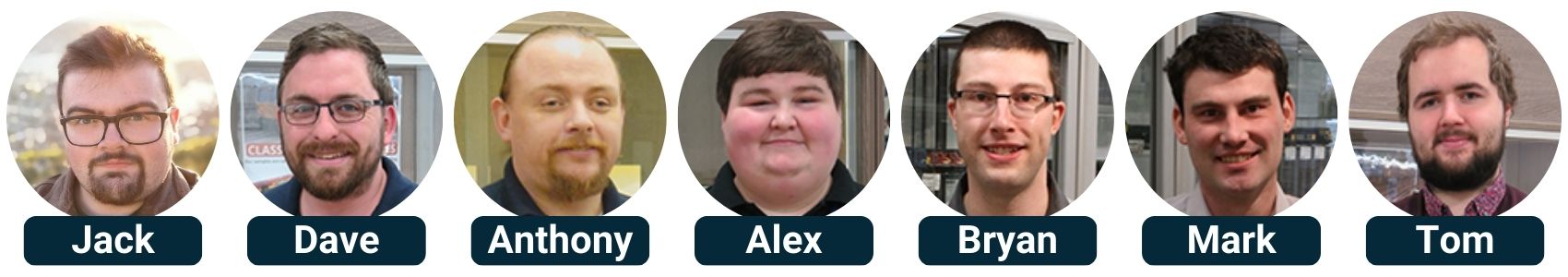

This information is maintained by our team of Product Experts. Please don’t hesitate to get in touch if you have any feedback or questions about this content.